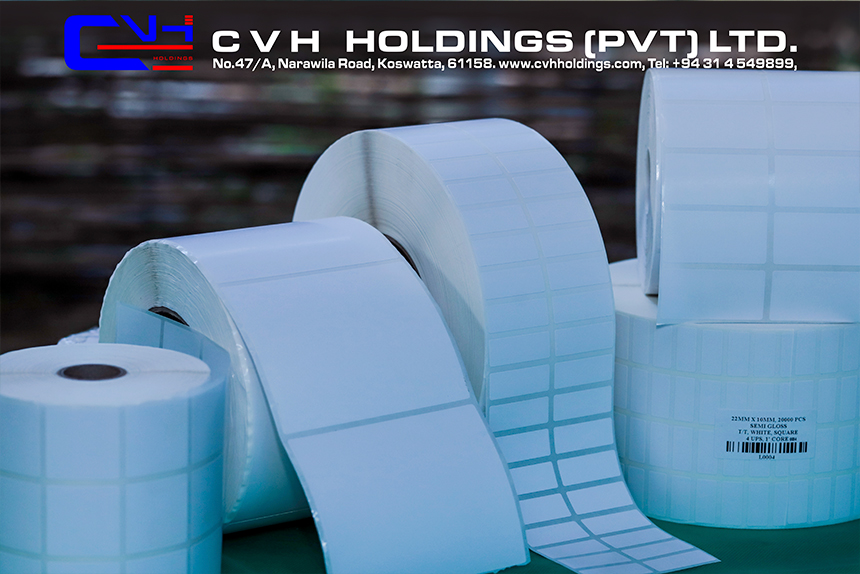

Thermal transfer labels are the perfect solution for companies printing large volumes of shipping and barcoding labels. These labels are more durable than the direct thermal alternative as they require a ribbon to print. In thermal transfer printing, the heating elements of the print head apply punctual heat to the passing ribbon, causing it to melt onto the label and form the print image. The label absorbs the ink so that it becomes part of the media.The most common thermal transfer applications include: product labeling and identification; long term storage, permanent identification; sample and file tracking; asset tagging; inventory identification; certification labels such as UL/CSA; laboratory specimens; cold storage and freezers; and outdoor applications.

Direct thermal labels are a cost-effective type of label made with the direct thermal printing process. In this process, a thermal print head is used to selectively heat specific areas of coated, thermo-chromatic (or thermal) paper. The paper runs over the thermal print head then turns black where it’s heated, producing a desired image. Two-color direct thermal printing can create both red and black images by applying heat at two temperatures. Direct thermal labels use no ink, toner or ribbon, only chemically treated, heat-sensitive materials. Time savings during the printing process, since thermal printing eliminates the need to monitor and reload ribbons. Direct thermal materials are highly sensitive to light, heat and heavy contact, making them susceptible to fading in the long term.

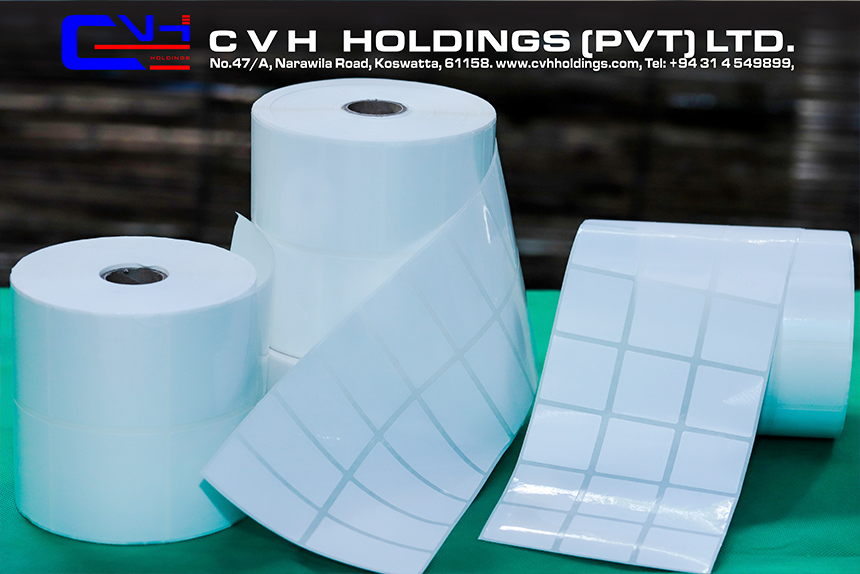

BOPP is a popular label material made of plastic. It stands for Biaxially-Oriented (BO) Polypropylene (PP). Biaxially-oriented refers to the production process that stretches the film over two directions, making it stronger and more transparent. It is made of plastic and not paper, BOPP is water and oil resistant. It is tear-resistant too, making it an excellent choice for uses that might get wet or messy. However, even though it is durable, we don’t recommend it for outdoor purposes.

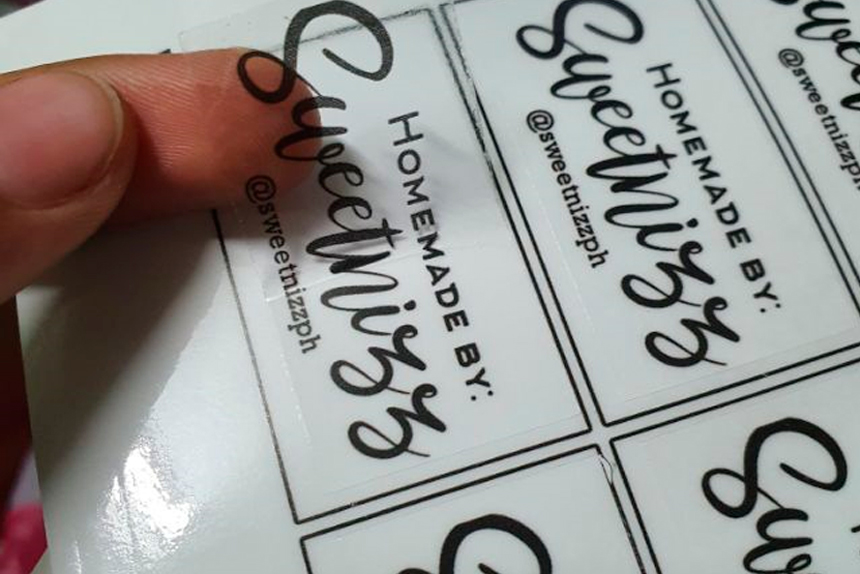

The adhesive on these labels is a high sticky acrylic based adhesive that provides strong initial grip as well as excellent long term adhesion that is suitable for a wide range of surfaces. A label’s adhesion depends on four factors; the strength of the adhesive, the length of time the label is stuck onto an item, the temperature, and the surface onto which the label is applied. These four interact with each other. Common applications for our high tack labels include security companies, storage and transportation of goods, the food industry, and manufacturers who apply these labels to surfaces as varied as metal pipes, wooden logs, and fabric samples.

Transparent or clear labels are usually printer specific. That means you have to use adhesive label material coated specially for either laser printing, or inkjet printing. Transparent labels are, well, labels that are transparent. They are made using materials that you can see through – our labels are made of transparent polyester and transparent adhesives. Our labels are all made of transparent materials, so they are not frosted or translucent.

A wax ribbon is a ribbon coated with an ink made essentially with wax-based components. Wax ribbons are the most popular thermal transfer ribbon for thermal printers. Wax ribbons will deliver a great print quality on the following label materials: Rough vellum papers. Matt coated papers. Thermal ribbons are a critical component in thermal transfer printing. In this print method, a hot print head creates the printed image by melting the ribbon material onto the paper stock. Thermal-printing technology can be used to produce color images by adhering a wax-based ink onto paper. As the paper and ribbon travel in unison beneath the thermal print head, the wax-based ink from the transfer ribbon melts onto the paper. When cooled, the wax is permanently adhered to the paper. All types of thermal transfer ribbons share a similar shelf-life. They expire within one to two years if unopened.

Thermal printers work by producing an image on paper using heat. The thermal printing process heats thermal paper with a special dye coating that turns black when it is heated. This process mostly appear in Direct Thermal label printing. Thermal transfer labels use a ribbon coated with dye in the ribbon paper to print and the print is for a long term apperance. Our company provides both direct thermal and thermal transfer printing services to our kind customers.

We, provide the most commonly used thermal label printing machines with all kinds of worldwide genuine brands. Mostly, we recommend the label printers such as TSC, Zebra, GT-Printers and so on. As per the amount of the labels to be printed, the machines will be supplied in two types. For a small amount of label printing jobs, we provide desktop printing machines that can be used domestically. But for massive printing purposes, we recommend the industrial thermal label printing machines. There are many types of thermal labels printing machines such as,